If you want to launch a line that stands out, you need to know how to get a clothing sample made with the right clothing sample maker. High-quality samples set the tone for your clothing line and show buyers what your brand can do.

When you choose a clothing sample manufacturer like Friendtex, you trust experts who understand what high-quality clothing manufacturers deliver. You work with a clothing sample maker who listens to your vision and helps you launch a line that feels unique. With the right manufacturer, you can see your ideas come to life.

Key Takeaways

Prepare your design materials carefully, including fabric choices and a detailed tech pack, to give your manufacturer a clear blueprint.

Choose a clothing sample manufacturer who matches your goals, offers the right services, and values clear communication to avoid costly mistakes.

Share your vision clearly with sketches, measurements, and detailed notes to help your manufacturer create samples that match your expectations.

Expect to review and revise your samples multiple times; giving clear, timely feedback speeds up the process and improves results.

Consider costs, minimum order quantities, and quality control when selecting a manufacturer, and choose sustainable options to support your brand and the environment.

Preparation Steps

Design Materials

Before you reach out to a manufacturer, you need to gather your design materials. This step sets the foundation for your clothing sample. Start by thinking about the fabric.

Each fabric type—natural, synthetic, or blended—brings something different to your design. Cotton and silk feel soft and breathable, while polyester and nylon add durability and easy care. Blended fabrics can give you the best of both worlds.

Consider these factors when choosing fabric:

Texture and weight

Drape and stretch

Durability and care needs

Color and texture combinations

Seasonal use (lightweight for summer, heavier for winter)

Tip: Talk to fabric suppliers or industry experts. They can help you pick the right material for your vision and offer advice on quality.

Tech Pack Essentials

A tech pack acts as your blueprint. It tells the manufacturer exactly how to make your sample. If you want to avoid mistakes, you need to include all the key details. Here’s what you should have in your tech pack:

Key Component | What to Include |

|---|---|

Fashion Flat Sketches & CADs | Simple sketches from all angles, clear notes, and digital views with colorways |

Bill of Materials (BOM) | List of all fabrics, trims, labels, and packaging with supplier info |

Measurement Specs | Size charts and detailed measurements with tolerances |

Cost Sheets | Breakdown of material, labor, and processing costs |

Extra Details | Colorways, mood boards, construction notes, packaging, and labeling info |

When you hand over a complete tech pack, you make the process smoother and faster.

Budget and Timeline

You need to set a clear budget and timeline before you start. Think about how much you can spend on materials, sampling, and revisions. Samples often need tweaks, so plan for extra costs. Decide when you want your first sample and when you hope to launch your line.

Make a simple checklist:

Set your total budget for sampling.

List all expected costs (materials, labor, shipping).

Build in a buffer for unexpected changes.

Create a timeline for each step, from design to final approval.

Planning ahead helps you avoid surprises and keeps your project on track.

How to Get a Clothing Sample Made?

You want to know how to get a clothing sample made that truly reflects your brand. The process can feel overwhelming, but when you break it down, it becomes much more manageable. Let’s walk through the steps together so you can move from idea to finished sample with confidence.

Choosing a Clothing Sample Manufacturer

Finding clothing sample manufacturers is one of the most important steps in launching your line. The right clothing sample maker will help you avoid costly mistakes and delays. Here’s how you can choose the best partner for your project:

Define Your Goals

Start by setting clear goals for your product and brand. Decide on your budget, the quality you expect, and the timeline you need.Check Capabilities

Make sure the manufacturer offers the services you need. Some provide a full production package, while others focus on cut, make, and trim (CMT). Ask about their experience with similar products.Review Certifications and References

Look for certifications that match your brand values, like organic or fair trade. Ask for references from other brands to see if the manufacturer is reliable.Prepare a Detailed Tech Pack

A complete tech pack helps the clothing sample maker understand your vision. Include sketches, measurements, materials, and construction details.Discuss Sample Creation

Talk to the manufacturer about making your first samples. Ask about their process, timelines, and how many revisions they allow.Set Clear Payment Terms

Use secure payment methods and agree on terms before you start.

Tip: Don’t rush this step. Take your time to find a manufacturer who matches your needs and values. This choice can make or break your project.

Friendtex’s One-Stop Solution

When you want a smooth experience from start to finish, Friendtex stands out as a leading clothing sample manufacturer. They offer a one-stop solution that covers every stage of how to get a clothing sample made. Here’s what makes Friendtex different:

Fast and Flexible Sampling

Friendtex delivers standard samples in 7–10 working days and rush orders in just 3 days. This speed helps you keep your project moving.Premium Materials

You can choose from high-end fabrics like Tencel, Modal, organic cotton, and bamboo. Friendtex’s focus on quality ensures your samples look and feel great.Customization for Every Brand

Whether you need petite, plus sizes, or special branding like embroidery, Friendtex offers extensive customization. Light customization options help small brands reduce inventory risk.Sustainability and Certifications

Friendtex uses eco-friendly materials and holds certifications like GOTS, OEKO-TEX, and Better Cotton Initiative. If sustainability matters to you, this is a big plus.Professional Support

The Friendtex team guides you through every step, from design drawings to final delivery. Their advanced technology and strict quality control mean you get reliable results.Small Batch Support

You don’t need to order huge quantities. Friendtex supports small batch orders, making it easier for new brands to get started.

Friendtex’s one-stop solution takes the stress out of finding clothing sample manufacturers. You get everything you need in one place, with a team that cares about your success.

Sharing Your Vision

Clear communication is the secret to getting the sample you want. When you work with a clothing sample maker, you need to share your ideas in a way that leaves no room for confusion. Here’s how you can do that:

Research Manufacturer Preferences

Every manufacturer has their way of working. Ask about their preferred file formats, measurement units, and templates before you send anything.Use Clear Visuals

Include sketches, CAD drawings, or photos from different angles. Label everything with color codes and notes so nothing gets missed.Provide Detailed Measurements

Give size charts, spec sheets, and grading information. Be specific about fit and tolerances.List All Materials and Trims

Create a bill of materials that covers every fabric, button, zipper, and label. Add details about quality and source.Add Construction Notes

Write out any special instructions or steps for assembling the garment. Mention quality standards and anything unique to your design.Send Real Samples if Possible

If you have a physical sample, send it to the manufacturer. This helps them understand your expectations.Stay in Touch

Keep communication open. Respond quickly to questions and provide feedback on samples. This helps avoid delays and mistakes.

A detailed tech pack acts like an instruction manual for your clothing sample maker. It saves time, reduces errors, and helps you get the sample you want on the first try.

If you follow these steps, you’ll know exactly how to get a clothing sample made that matches your vision. With the right manufacturer, like Friendtex, and clear communication, you set yourself up for a successful launch.

Clothing Sample Development Process

Getting your clothing line off the ground means understanding the clothing sample development process from start to finish. You want to make sure every detail matches your vision, and that’s where working with an experienced manufacturer like Friendtex pays off.

Let’s break down what you can expect, from your first samples to the final approval.

First Samples

The journey begins when you send your tech pack and design materials to your manufacturer. This step sets everything in motion. Here’s a typical timeline you might follow:

Send your tech pack and any physical swatches to the factory. This can take just a few minutes if you send files online, or up to a week if you ship fabric samples.

The factory reviews your materials and starts producing your first samples. For simple designs, you might see results in about 10 days. More complex pieces can take up to three weeks.

If your manufacturer is overseas, add a few days for shipping and customs.

Once you receive your first samples, you review them and give feedback.

The factory uses your comments to make any needed changes and prepares the next round of samples.

Tip: Friendtex’s team moves quickly, often delivering standard samples in 7–10 working days. You get to see your ideas come to life without long waits.

Iterative Adjustments

You probably won’t get a perfect sample on the first try. That’s normal! The real magic happens during the adjustment phase. Here’s what you and your manufacturer will focus on:

Fit tweaks: You might need to adjust the bust, shoulders, or neckline to get the right fit.

Dart changes: Sometimes, you’ll add or move darts to shape the garment just right.

Adding fullness: Pleats, gathers, or pintucks can give your design more volume or style.

Slash and spread: This technique lets you change the shape of a piece, like turning a straight skirt into an A-line.

Pattern grading: Once you’re happy with the fit, the manufacturer will grade the pattern for different sizes.

You’ll go back and forth with your manufacturer, sharing feedback and reviewing new samples. Friendtex makes this easy by keeping communication clear and offering expert advice at every step.

Note: The most common reasons for sample rejection include poor workmanship, misunderstandings between you and the factory, using substitute materials, late feedback, or not having a clear checklist. Staying organized and giving prompt, detailed comments helps you avoid these issues.

Reason for Sample Rejection | Explanation |

|---|---|

Poor workmanship | Tailoring quality does not meet buyer specifications or standards. |

Lack of understanding between buyer & house | The sample development team misunderstands buyer requirements, leading to samples that don’t match. |

Non-availability of actual trims and fabrics | Using substitute materials causes samples to fail buyer expectations. |

Late comments from the buyer | Delayed feedback from buyers causes delays and repeated revisions. |

No defined checklist from the buyer | Inconsistent or late comments lead to multiple rounds of sample corrections. |

Final Approval

When you’re happy with the adjustments, it’s time for final approval. This step is all about quality assurance. Here’s how you and your manufacturer make sure everything is perfect before production:

The factory creates several types of samples, like proto samples, fit samples, and pre-production samples (PPS).

You or a third-party inspector checks the PPS for fabric, color, trims, and overall quality.

You approve the PPS, giving the green light for bulk production.

During production, the factory keeps checking quality by collecting top-of-production (TOP) samples.

They use random sampling methods, like AQL, to spot any defects.

Before shipping, the factory takes final shipment samples for last-minute checks.

Third-party inspections confirm that the bulk order matches your approved sample.

Friendtex stands out here. Their team manages every step, from the first sample to the final sample, using strict quality control and sustainable practices. You get peace of mind knowing your clothing line will meet high standards and wow your customers.

Pro tip: Give clear, timely feedback and keep your checklist up to date. This helps your manufacturer deliver exactly what you want, right on schedule.

Key Considerations

Costs and MOQs

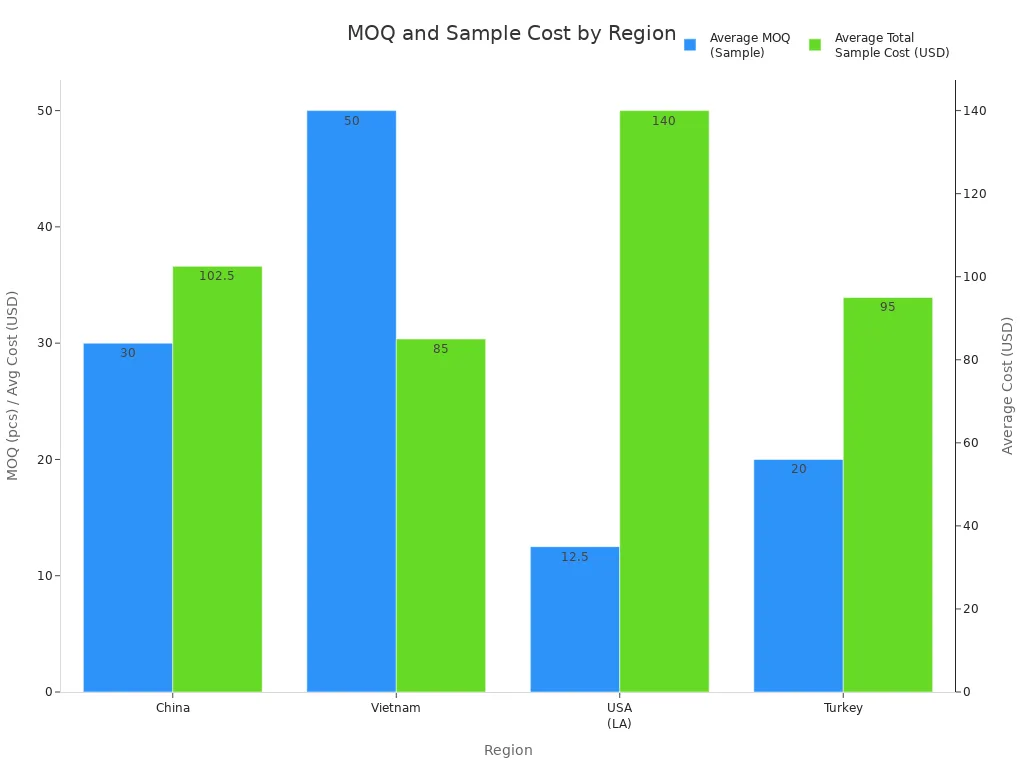

When you start working with a clothing sample maker, you need to know what to expect for costs and minimum order quantities (MOQs). Prices and MOQs can change a lot depending on where your manufacturer is located. Here’s a quick look at how things compare:

Region | MOQ (Sample) | Lead Time | Total Cost Range (USD) |

|---|---|---|---|

China | 30 pcs | 3–5 weeks | $75–$130 |

Vietnam | 50 pcs | 4–6 weeks | $60–$110 |

USA (LA) | 5–20 pcs | 1–2 weeks | $80–$200 |

Turkey | 20 pcs | 2–3 weeks | $70–$120 |

You’ll also want to budget for extra fees like sample charges, shipping, and pattern making. Local clothing sample makers in the US often cost more but can deliver samples faster. Overseas options usually have higher MOQs but lower base prices. Always ask your manufacturer for a full breakdown before you commit.

Tip: If you’re just starting, look for a clothing sample maker who supports small batch orders. This helps you test your designs without a huge upfront investment.

Quality Control

Quality control keeps your samples looking sharp and your brand’s reputation strong. Every good manufacturer follows a set of steps to make sure your clothes meet high standards. Here’s what you can expect:

Before production, the team checks all fabrics for defects and tests for things like shrinkage and colorfastness.

During production, workers inspect their work, and trained inspectors check stitching, seams, and measurements.

After production, the factory checks for loose threads, stains, and label accuracy. Sometimes, a third-party inspector reviews everything before shipping.

You’ll see tests for fabric strength, colorfastness, and seam quality. Many factories follow international standards like ISO 9001 and AATCC. If you want extra peace of mind, you can ask for third-party lab testing or audits.

Note: Clear communication with your clothing sample maker helps catch problems early and keeps your samples on track.

Sustainable Practices at Friendtex

Sustainability matters more than ever in fashion. Friendtex leads the way by using eco-friendly materials like organic cotton, bamboo, and recycled polyester. These choices use less water, fewer chemicals, and create less pollution than traditional fabrics.

For example, organic cotton uses much less water than regular cotton, and bamboo grows quickly without pesticides.

Friendtex also uses sustainable dyeing methods and works to reduce waste with smart cutting and recycling. The company holds certifications like GOTS and OEKO-TEX, showing a real commitment to the planet.

You can feel good knowing your samples come from a clothing sample maker that cares about both quality and the environment.

Choosing a sustainable manufacturer helps your brand stand out and supports a better future for fashion.

Next Steps After First Samples

Feedback and Revisions

You just received your first samples. Now it’s time to check every detail and make sure they match your vision. Start by measuring the garment before you try it on. Lay it flat and compare the measurements to your original specs.

Highlight anything that doesn’t match. Next, look at the construction. Check pockets, buttons, and stitching. Do they line up with your tech pack?

Put the sample on a model or dress form that matches your base size. Look for drag lines, stress points, or anything that feels off. Write down your comments in a clear, organized way. Use bullet points to list what needs fixing. Add photos or sketches to show exactly what you mean.

Be direct and specific. For example, say “Move pocket up 2 cm” instead of “Pocket looks low.” Update your tech pack with these changes and send it back to your manufacturer. This helps everyone stay on the same page and keeps the process smooth.

Tip: Consistent, clear feedback builds a strong relationship with your manufacturer and helps you get better results with fewer rounds of revisions.

Moving to Production with Friendtex

Once you approve your samples, you’re ready to move into production. This step is all about making sure your design is ready for mass production and that you have everything in place for a smooth launch. Here are some key factors to keep in mind:

Step | What You Need to Do |

|---|---|

Design Refinement | Make final tweaks based on sample feedback. |

Manufacturing Prep | Work with Friendtex to set up efficient processes and quality checks. |

Material Sourcing | Confirm all fabrics and trims are available and meet your standards. |

Pilot Production Run | Start with a small batch to test the process and catch any last-minute issues. |

Full-Scale Production | Ramp up to larger quantities once everything looks good and reliable. |

Friendtex guides you through each stage. Their team helps you refine your design, source high-quality materials, and set up quality control. You can trust them to handle the details, so you can focus on growing your brand.

With clear communication and a reliable partner, you’ll move from first samples to full production with confidence.

Conclusion

You now know how to get your clothing line started with the right clothing sample maker. Start with strong prep, pick a clothing sample maker who gets your vision, and keep your ideas clear.

High-quality samples help your line stand out. Friendtex is a clothing sample maker you can trust for every step, from your first line to your next big launch. Ready to see your line come to life? Take that first step with a clothing sample maker who cares about your success.

FAQ

How long does it take to get a clothing sample made?

You can usually expect your first sample in about 7–10 working days with Friendtex. If you need it faster, rush orders can be ready in just 3 days. Timelines may vary based on design complexity.

What should I include in my tech pack?

Make sure your tech pack has clear sketches, measurements, fabric choices, and construction notes. Add any special details or branding you want. The more info you give, the smoother the process will be.

Can I order a small batch of samples?

Yes! Friendtex supports small batch orders. This helps you test your designs without a big upfront investment. You can start small and scale up when you’re ready.

What fabrics can I choose from with Friendtex?

You get access to premium fabrics like Tencel, organic cotton, bamboo, Modal, and more. Friendtex offers eco-friendly options and a wide range of colors and textures to match your vision.

How do I give feedback on my samples?

Try these steps:

Measure the sample and compare it to your specs.

Check fit and construction.

List changes clearly, using photos or notes.

Send your feedback quickly so the process keeps moving.